When it comes to maintaining the integrity and longevity of industrial piping systems, customized expansion joints lined with PTFE (tetrafluoroethylene) offer excellent resistance to corrosive chemicals, high temperatures, and mechanical stresses. If you are struggling with premature wear in your piping system due to harsh conditions, PTFE-lined expansion joints can provide an effective solution.

PTFE-lined expansion joints provide long-term reliability, reduce maintenance costs, and protect against chemical degradation, especially in environments like chemical processing, pharmaceuticals, and food manufacturing.

Here’s why a PTFE-lined expansion joint may be the right choice for your system.

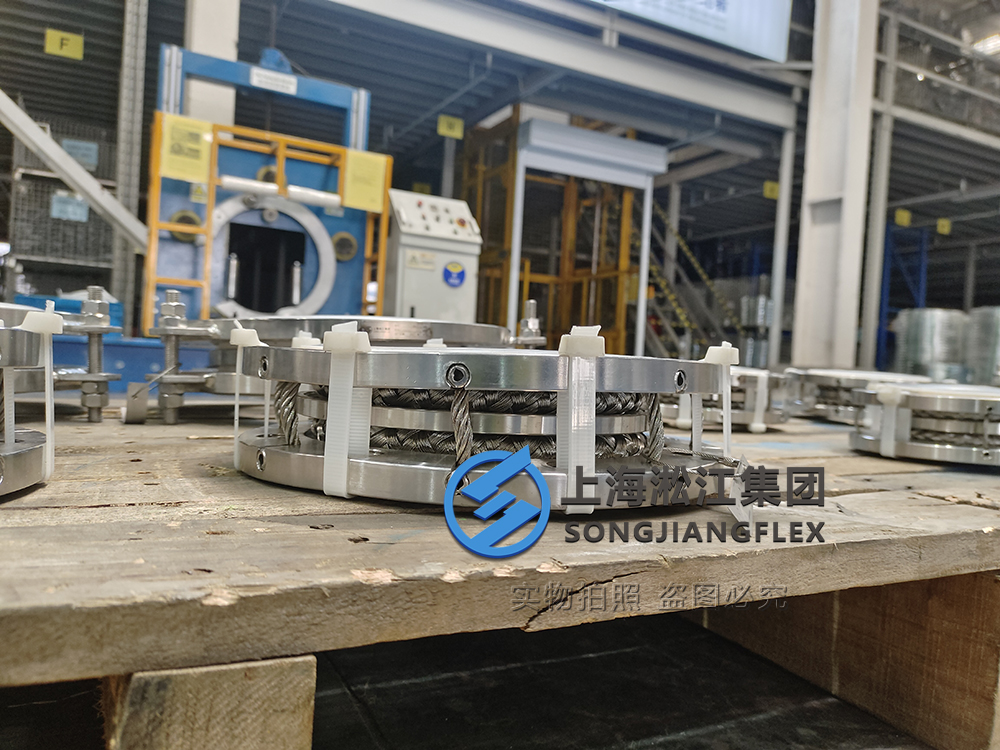

What is a PTFE-lined expansion joint?

A PTFE-lined expansion joint is a specialized component used to compensate for the thermal expansion and contraction of pipelines while also protecting against chemical corrosion. The PTFE lining provides superior resistance to aggressive substances and helps the expansion joint maintain its flexibility even in high-temperature environments.

PTFE-lined expansion joints offer the perfect solution in industries where extreme temperatures and aggressive chemicals are part of daily operations, ensuring both safety and long-lasting performance.

In addition to being chemically inert, PTFE provides excellent non-stick properties, making it highly resistant to fouling, thus reducing the need for frequent maintenance.

What is a PTFE expansion joint?

A PTFE expansion joint is designed with a PTFE liner to handle both mechanical movements in pipelines and protect against corrosion. PTFE is especially valuable in chemical industries due to its resistance to acids, alkalis, and other harsh chemicals.

By choosing PTFE expansion joints, you’re selecting a material that excels in both flexibility and chemical resistance, ideal for handling corrosive media and extreme temperatures in industries like chemical processing and pharmaceuticals.

With their ability to absorb vibrations and accommodate movement, PTFE expansion joints ensure long-lasting, smooth operation of pipeline systems.

Why customize an expansion joint with PTFE lining?

Customization allows you to tailor expansion joints to the specific requirements of your system, ensuring better performance and a longer operational life. In particular, PTFE lining can be customized to handle specific chemical compositions and temperature ranges that are unique to your environment.

Customized PTFE-lined expansion joints optimize the compatibility between your piping system’s needs and the joint’s material, leading to reduced wear and lower long-term maintenance costs.

Rubber expansion joint manufacturers offer customization options to ensure the perfect fit for your system’s specifications, whether in terms of size, material selection, or load-bearing capacity.

What are the advantages of expansion joints?

Expansion joints play a crucial role in absorbing the movements caused by thermal expansion and contraction, vibration, and mechanical stress in piping systems. They help protect the system from damage and ensure its smooth operation.

Expansion joints allow pipelines to expand and contract without causing damage, reducing stress and preventing cracks, leaks, and other failures in the system.

In addition, rubber expansion joints provide flexibility and can be used in systems requiring both thermal and vibration management, ensuring that pipes remain intact even under challenging conditions.

What is the main purpose of expansion joints in steam lines?

In steam lines, the purpose of expansion joints is to compensate for thermal expansion caused by the high temperatures of the steam. Without expansion joints, the heat would cause significant stress on the pipes, which could lead to cracks, leaks, and failure of the system.

Expansion joints help steam pipelines accommodate expansion while protecting the structural integrity of the system.

Rubber bellows expansion joints, for instance, provide the flexibility needed in steam lines, preventing damage from thermal expansion and vibration.

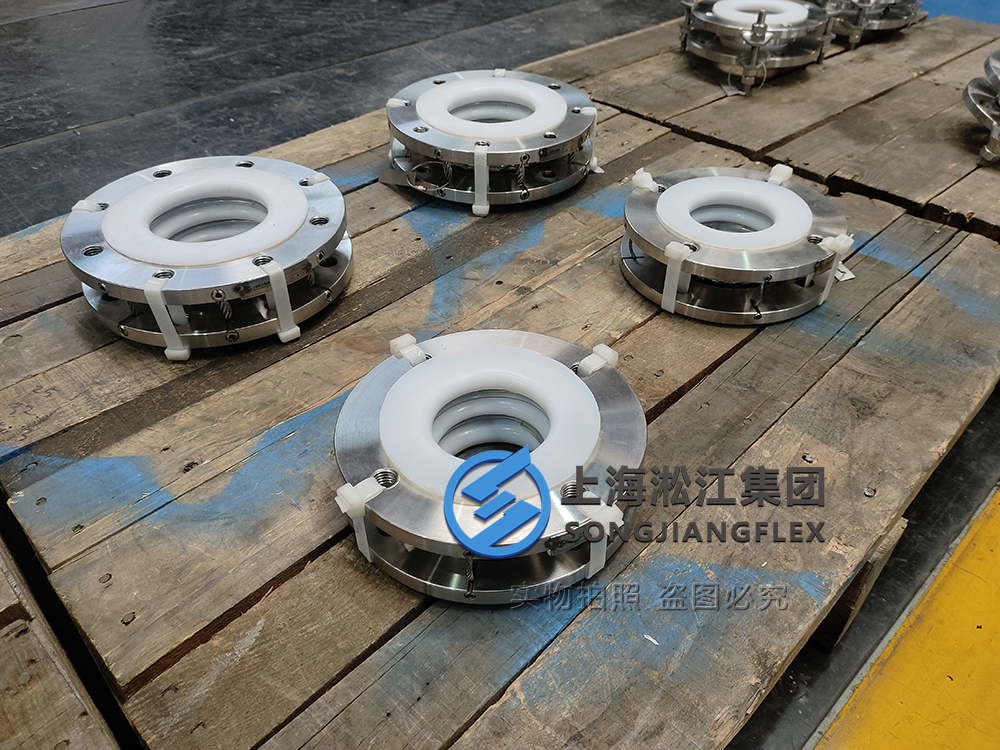

What is the use of PTFE liner?

PTFE liners are used to protect the inner surface of expansion joints from corrosive chemicals and high temperatures. This makes PTFE-lined expansion joints ideal for applications in chemical processing plants, food manufacturing, and pharmaceutical industries, where aggressive media could otherwise damage the pipeline system.

PTFE liners enhance the lifespan of expansion joints by providing superior chemical resistance, even in the most demanding environments.

Additionally, PTFE’s non-stick properties help prevent product buildup inside pipelines, which is crucial in industries where cleanliness is essential.

What are the advantages of PTFE?

PTFE, commonly known as Teflon, is renowned for its excellent chemical resistance, high-temperature tolerance, and low friction coefficient. It is ideal for use in expansion joints as it offers both durability and flexibility under harsh conditions.

The key advantages of PTFE include resistance to almost all chemicals, a wide operating temperature range, and its non-stick properties, making it an excellent material for lining expansion joints.

In many industries, including pharmaceuticals and chemical processing, PTFE is a preferred material because it minimizes contamination risks and withstands corrosive chemicals.

What is expanded PTFE used for?

Expanded PTFE (ePTFE) is a versatile material used in various industrial applications, including gaskets, seals, and filtration systems. Its unique structure makes it both flexible and highly durable, allowing it to handle extreme environments.

ePTFE is commonly used in sealing applications where chemical resistance and durability are critical, such as in chemical processing and aerospace industries.

Its flexibility also makes it an ideal material for expansion joints in systems that handle highly corrosive media, ensuring long-lasting protection.

How does PTFE lining improve the longevity of expansion joints?

PTFE lining enhances the durability of expansion joints by protecting them from chemical attack, high temperatures, and mechanical stresses. It ensures that the joints remain flexible and effective over long periods, even in aggressive environments.

By reducing the impact of chemical corrosion and minimizing wear, PTFE-lined expansion joints significantly extend the lifespan of piping systems, reducing the need for frequent repairs and replacements.

Rubber expansion joints, when combined with PTFE lining, offer both flexibility and chemical resistance, making them ideal for a variety of industrial applications.

Summary

PTFE-lined expansion joints provide unparalleled protection against chemical corrosion and high temperatures, making them a reliable solution for industries that demand durability and flexibility in their piping systems.

If the original article is reprinted, please indicate the link of this article:https://www.pipeline-expansion-joint.com/what-are-the-benefits-of-a-customized-expansion-joint-with-a-tetrafluoroethylene-ptfe-lining.html

![[Clamp] pipeline expansion joints “instead of flanges”](https://pipeline-expansion-joint.com/wp-content/uploads/2022/05/Clamp-Pipeline-Expansion-Joint.jpg)

![[Rubber Joint Contract for the Expansion Project of GAC Toyota New Energy]](https://www.pipeline-expansion-joint.com/wp-content/uploads/2025/02/Rubber-Isolators-for-the-Expansion-Project-of-GAC-Toyota-New-Energy.jpg)